What to Expect During Expert Pneumatic Cylinder Rebuild

In industries where uptime is critical, understanding what goes into a pneumatic cylinder rebuild in Virginia Beach, VA, can make a major difference in maintaining operations. HyVal Industries, a trusted provider in the area, offers expert repair services tailored to the needs of local businesses across manufacturing, construction, and marine sectors. Whether you're managing a fabrication plant or overseeing heavy equipment, gaining clarity on the rebuild process helps you make smarter, more cost-effective decisions.

Understanding the Rebuild Process

A professional pneumatic cylinder rebuild in Virginia Beach, VA, follows a detailed process designed to restore full functionality and extend equipment life. Here's a breakdown of what that involves:

1. Disassembly and Cleaning

Technicians start by disassembling the cylinder and thoroughly cleaning every component. Removing built-up grime and debris is critical for spotting internal wear and preventing further damage.

2. Inspection and Evaluation

Each part—barrel, piston, rod, and end caps—is carefully inspected. This step identifies corrosion, scoring, and other forms of wear that affect performance. Evaluations determine which components can be refurbished and which require replacement.

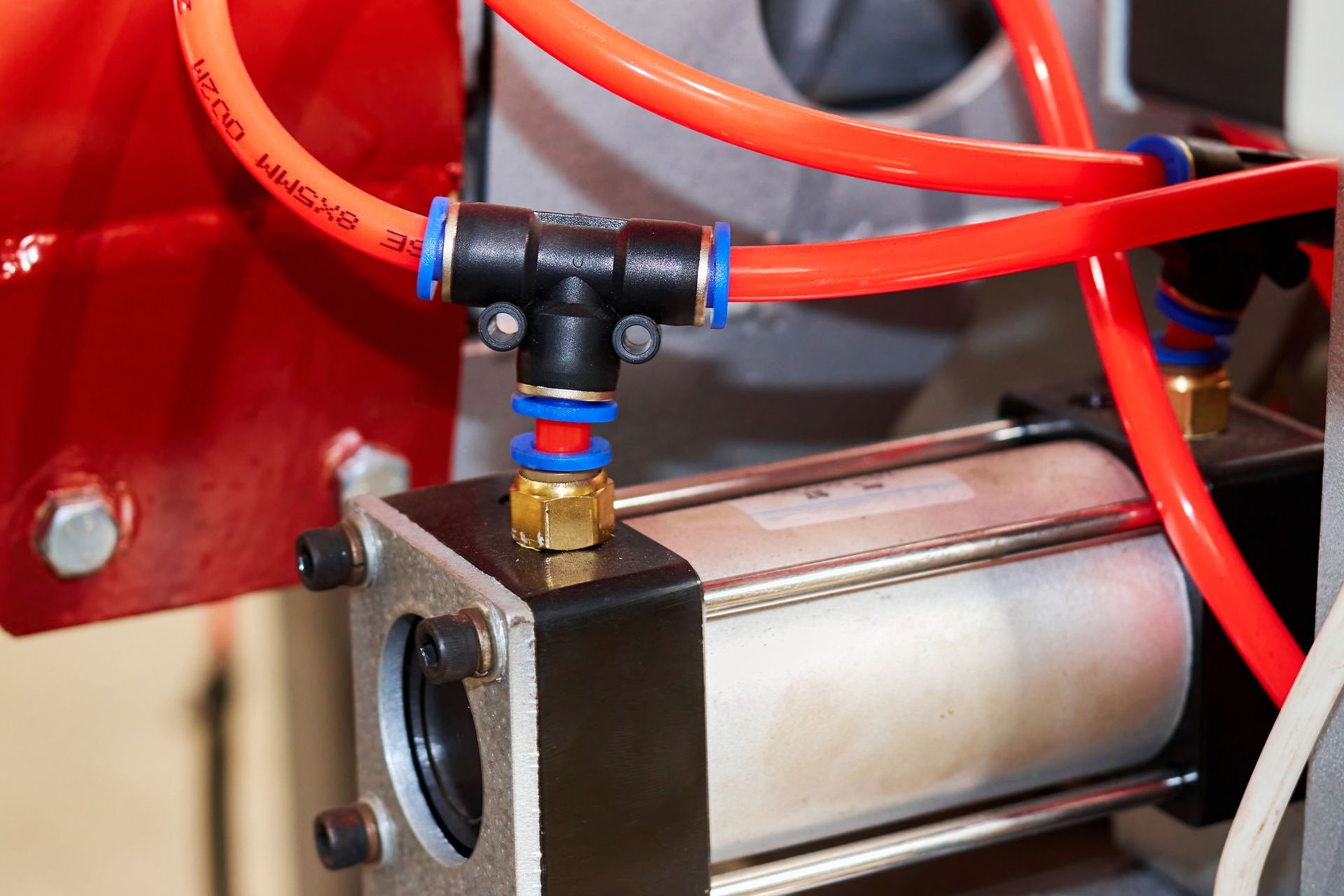

3. Seal and Component Replacement

Worn seals and damaged parts are replaced with high-quality alternatives that meet or exceed OEM standards. Replacing seals is especially vital for preventing air leakage and pressure loss.

4. Reconditioning Critical Surfaces

Technicians machine or polish damaged surfaces to restore their original specifications. This helps ensure proper sealing, reduces friction, and enhances long-term performance.

5. Reassembly and Pressure Testing

Once all repairs and replacements are complete, the cylinder is reassembled and undergoes rigorous pressure testing. This ensures it’s ready to resist real-world demands before it’s returned to service.

HyVal Industries applies this methodical process to every rebuild, helping clients reduce downtime and avoid costly equipment failures.

Why Local Expertise in Virginia Beach Matters

Choosing a local provider for your pneumatic cylinder rebuild in Virginia Beach, VA, offers significant advantages. Virginia Beach industries—from shipbuilding and defense to commercial construction—have unique performance requirements and tight production timelines. A regional partner like HyVal Industries understands these conditions and is well-positioned to respond quickly, even during emergency rebuilds.

In addition, local expertise means better familiarity with environmental impacts on equipment, quicker parts sourcing, and personalized customer service. With HyVal Industries, you're working with a team that’s not just technically proficient but also invested in the success of your operations.

Planning for Longevity and Reliability

Routine maintenance and timely rebuilds help keep pneumatic systems running efficiently. Compared to full replacements, rebuilds are often faster and more cost-effective, especially when performed by experienced professionals. A properly rebuilt cylinder can match the performance of a new one, giving you more value and fewer interruptions.

Get Expert Pneumatic Cylinder Rebuild Services in Virginia Beach, VA

When your equipment starts showing signs of inefficiency or failure, don’t wait for a complete breakdown. A professional pneumatic cylinder rebuild in Virginia Beach, VA, can restore your systems and protect your bottom line. To learn more or request service, connect with the team at HyVal Industries —your local resource for reliable pneumatic solutions in Virginia Beach, VA.